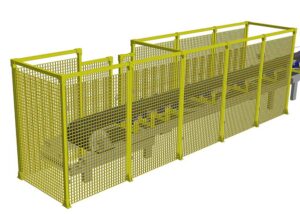

Fibreglass Modular Guarding System

Our modular FRP guarding system protects machinery, conveyors, and restricted zones with clean lines and high visibility. We use FRP to remove common pain points with painted steel in wet or chemically aggressive areas. Panels, posts, and doors are supplied as stock panels and post lengths with matching hardware packs for efficient site fabrication and assembly. The system installs quickly, stays tidy, and resists corrosion and chemical attack. We also supply steel guarding, and we often combine FRP and steel in the same project to suit different zones, impacts, and budgets, with steel available as pre-engineered kits where appropriate.

-

- Complies with AS/NZS 4024.3610:2015

- Complies with AS 4024.1:2014

Safety and Quality Above the Standard

What Sets us Apart

We are a New Zealand family-owned and operated company with a fully equipped workshop in the Bay of Plenty. We provide an in-house cutting service supported by advanced equipment and proven fabrication methods, and we can accommodate non-standard sizes and finishes when required. Our team is always ready with technical support and practical design guidance, and we maintain significant stock on-site to keep lead times short and projects moving.

-

Production Oversight

Our products are produced exclusively through accredited manufacturing partners that operate under ISO 9001 quality systems. This gives us direct control over specifications, consistency, and traceability.

-

Verified Testing and Compliance

Our products are independently tested and verified to recognised standards, supported by third-party laboratories and CPEng engineering where required, ensuring dependable performance.

-

Environmental Responsibility

We are guided by ISO 14001:2015 environmental management principles to reduce waste, improve efficiencies, and minimise our operational impact.

Our Modular FRP Guarding is a moulded Fibreglass Reinforced Polymer system designed to provide reliable perimeter protection, pedestrian guidance, and machinery separation across commercial and industrial sites. It is engineered for long service life in New Zealand conditions, offering stable performance in environments where steel guarding is prone to corrosion, chemicals, and ongoing repainting.

The system is lightweight and electrically non-conductive. Panels and posts are supplied as modular components that install quickly, stay tidy, and maintain their strength without routine surface coating or rust treatment. This makes it well suited for facilities aiming to minimise maintenance downtime.

Typical Applications: Machinery Guarding • Perimeter Fencing • Pedestrian Barriers • Plant Rooms • Processing Areas • Coastal or Chemical Environments

All guarding infill panels are manufactured using moulded FRP grating technique, combined with precision pultruded structural framing. This ensures consistent fibre alignment, dependable mechanical performance, and clean, accurate geometry throughout the system.

Light Duty Mesh

All infill panels use a hand lay-up open-mould process that delivers full fibre wet-out, uniform resin distribution and stable bar geometry for long-term dimensional reliability.

Reinforcement: Continuous E-glass roving placed bidirectionally for balanced stiffness and impact performance.

Pultruded Structural Framing

Posts, rails, and perimeter framing are produced by continuous pultrusion to achieve high glass content, consistent fibre orientation and low deflection under load. Profiles maintain tight tolerances, straightness, and smooth edges suitable for clean perimeter integration with moulded panels.

Hardware and Fasteners

All connection hardware, clips and panel fixings are supplied in 316 stainless steel. This provides strong mechanical fastening, long-term corrosion resistance and reliable performance in outdoor, coastal, chemical and wash-down environments.

Resin Systems

Isophthalic Polyester (ISO)

A dependable resin system suitable for most guarding applications. Good UV stability, moisture resistance and mechanical strength at a competitive price point.

Full resin comparison is available in our “Resin Comparison – ISO vs VE vs Ortho” technical document.

Pigments and Additives

Pigments are VOC free. Fire retardants and UV inhibitors are blended into every batch during moulding and pultrusion to deliver long-term colour stability and reliable outdoor performance.

FIRE PERFORMANCE

- ISO 9239-1 / AS 9239.1 (Reaction to Fire for Flooring Materials) – Tested by NZWTA Laboratories (Reports 2018 & 2020).

Critical Radiant Flux (CRF): 10.9 kW/m² – Exceeds the 4.5 kW/m² requirement for NZ & Australia.

Smoke Value: ≈ 210 %.min – Very low smoke generation, excellent visibility retention.

Result: Fully compliant with NZ Building Code (C/VM2) and Australian NCC equivalence - ASTM E84 – Steiner Tunnel Test – SGS Report (Dec 2022).

Flame Spread Index (FSI): 20 • Smoke Developed Index (SDI): 400 Classification: Class A (≤ 25 FSI / ≤ 450 SDI) — highest U.S. rating.

DURABILITY & UV EXPOSURE

- ASTM G154 Accelerated UV Exposure – Samples exposed 2,500 hours (≈ 7–10 years real-world) showed no statistically significant strength loss

- Complies with NZ Building Code Clause B2 (Durability).

- Expected service life well beyond 15 years with routine maintenance.

MATERIAL SAFETY

- AS 4964 (Qualitative Identification of Asbestos) – Independent testing confirmed no asbestos detected in any FRP Limited product.

WATER ABSORPTION TESTING

Testing was carried out by SGS. in accordance with ASTM D570-22 on our moulded FRP products manufactured using ISO and VE resin systems.

TEST CONDITIONS:

Dried at 50 ± 2 °C for 24 h

Soaked in water at:

- 23 °C for 24 h

- 100 °C for 2 h

- 50 °C for 48 h

MEASURED WATER ABSORPTION (%):

| Condition | Sample A | Sample B | Assessment |

|---|---|---|---|

| 23°C / 24 h | 0.17% | 0.09% | Excellent resistance – negligible absorption |

| 100 °C / 2 h | 0.49% | 0.47% | High stability – minimal uptake under heat |

| 50 °C / 48 h | 0.52% | 0.71% | Strong retention – remains below 1% threshold |

INTERPRETATION:

Results demonstrate consistently low water absorption across all temperature and duration tests, confirming a dense, well-cured laminate structure.

Moisture uptake remained below 1%, supporting dimensional accuracy, mechanical reliability, and long-term surface integrity.

Performance levels are within the expected range for high-grade structural FRP composites and trend toward the lower end of typical absorption values, indicating slightly improved resistance compared with standard industry benchmarks.

LOW VOC PIGMENT

Our colour system utilises a polyester-based pigment dispersion that chemically bonds within the FRP matrix, rather than just coating it. This 100% solids, low-VOC formulation delivers cleaner processing, longer-lasting colour, and superior UV stability compared to solvent-borne alternatives. It’s a smarter, more sustainable way to colour FRP.

ELECTRICAL PROPERTIES – TESTING IN PROGRESS

- Arc Resistance (LW): ASTM D-495 – pending

- Dielectric Strength (LW): ASTM D-149 – pending

- Dielectric Strength (PW): ASTM D-149 – pending

SLIP RESISTANCE

- AS/NZS 4586 (Wet Pendulum Method) – Independently tested by ISTS (NATA Accredited).

- All surfaces classified V – Very Low Risk of Slip (BPN > 54).

- Complies with NZBC Clauses D1 (Access Routes) and F4 (Safety from Slipping).

ELECTRICAL INSULATION TESTING

Testing was carried out by SGS in accordance with ASTM D495-22 and ASTM D149-20 on our FRP moulded products manufactured using ISO and VE resin systems.

TEST CONDITIONS:

Dry Arc Resistance (ASTM D495-22)

- Arcing voltage: 12.5 kV • Electrode gap: 6.35 mm • Environment: 23 °C / 50 % RH

Dielectric Breakdown (ASTM D149-20)

- Transformer oil medium • Voltage rise: 3000 V/s • Frequency: 50 Hz

MEASURED ELECTRICAL PERFORMANCE:

| Property | Sample A (ISO resin) | Sample B (VE resin) | Assessment |

|---|---|---|---|

| Arc Resistance Time (s) | 182.5 s | 146.2 s | Excellent surface insulation – high resistance to tracking |

| Dielectric Strength (kV/mm) | 15.6 kV/mm | 12.5 kV/mm | Strong electrical barrier – stable under high voltage |

INTERPRETATION:

Results confirm both resin systems deliver high-grade electrical insulation consistent with the requirements of ASTM D495 and D149.

The ISO-resin laminate achieved the highest overall performance, showing extended arc-resistance duration and greater dielectric strength, indicating a dense, well-cross-linked matrix with minimal conductive pathways.

The VE-resin laminate also exhibited strong insulating capability, remaining well within the range expected for premium structural FRP composites.

Electrical performance across both systems supports their suitability for installations requiring high-voltage isolation, reduced surface tracking, and long-term reliability in wet or industrial environments.

Our Modular FRP Guarding system is designed to be simple to install, adaptable onsite and fully compliant when installed in accordance with our standard drawings and guidance notes. The system supports both new builds and retrofit projects where fixed dimensions are not always available at design stage.

Design Intent and Compliance

The guarding layout, post spacing and fixing points are engineered to meet the requirements of AS/NZS 4024.3610 and AS 4024.1. Compliance is achieved when the system is assembled using the specified components, fixing patterns and clearances shown in our drawings. General arrangement drawings, post details and fixing schedules are available for all standard configurations.

Onsite Fabrication

A key strength of this system is its ability to be trimmed, cut, and adjusted onsite using standard FRP cutting tools. Installers can adapt panels and rails around floor variations, concrete edges, service penetrations and existing equipment without compromising structural integrity. This reduces installation time and avoids the delays typically associated with fully prefabricated steel systems.

Installation Process

The system is assembled using 316 stainless hardware and mechanical fixings. Posts are positioned to the grid shown on the drawings and secured to the substrate before panels and rails are fitted. Infill panels can be cut to final size onsite and fastened directly to the pultruded frame. The result is a clean, rigid and corrosion-resistant installation that stays square and tidy over time.

Preferred Installers

We work with preferred installers nationwide who are familiar with FRP handling, cutting techniques and compliance requirements.

PDF Download

Return Roller Nip Guard

Our Return Roller Guard provides safety and functionality for operators without being complicated or interrupting productivity. It offers convenient access for roller inspection, cleaning, and maintenance. It is a practical solution that protects the return roller nip point while the conveyor operates. The return roller guard is constructed from stainless steel and FRP mesh, providing corrosion resistance for long service life. It is available to suit custom belt widths.

-

Compliant – AS/NZS 4024.1801:20144.2.4.1 and AS/NZS 4024.3611.2015.

-

Durable – Stainless steel and FRP construction for superior corrosion resistance.

-

Easy to Clean – Straightforward design allows for routine maintenance of the return roller.

-

Adjustable – UHMWPE blade allows for incremental adjustment when required.

-

Innovative Design – Return roller mounting slots have been incorporated into the design.

FRP Modular Guarding Drawing Pack

Request our Modular FRP Guarding Drawing Pack to receive the full set of technical details for designing and installing compliant guarding across industrial and commercial sites. The pack includes isometric layouts, access gate configurations, interlock lift out options and complete fitting tables with product codes and quantities. It shows how each panel, post and joiner connects, making it easier to plan accurate layouts and material take offs while meeting AS/NZS 4024 requirements.

Ideal for machinery guarding, pedestrian barriers, access gates and integration into wider project drawings. CAD models can also be provided on request.

Why Choose FRP Ltd

-

NZ Family-Owned and Operated

We understand what matters to you as a proudly NZ family-owned and operated business. We're dedicated to providing reliable, locally supported solutions that meet the needs of New Zealand industries.

-

Expertise and Quality

We offer our customers premium products that adhere to industry standards, ensuring durability and reliability.

-

Competitive Pricing

We deliver exceptional value by combining high-quality materials with cost-effective pricing, ensuring you receive the best products at a reasonable cost.

-

Proven Track Record

We are proud to have built a reputation nationwide and across industries for delivering reliable product solutions that meet and exceed customer expectations.

Have a Question? Get Product Advice.

We're here to help! If you have any questions, need support with a product, or would like a copy of the standards we adhere to, please don't hesitate to contact us. We look forward to assisting you!