Improves the anti-slip conditions on flooring surfaces

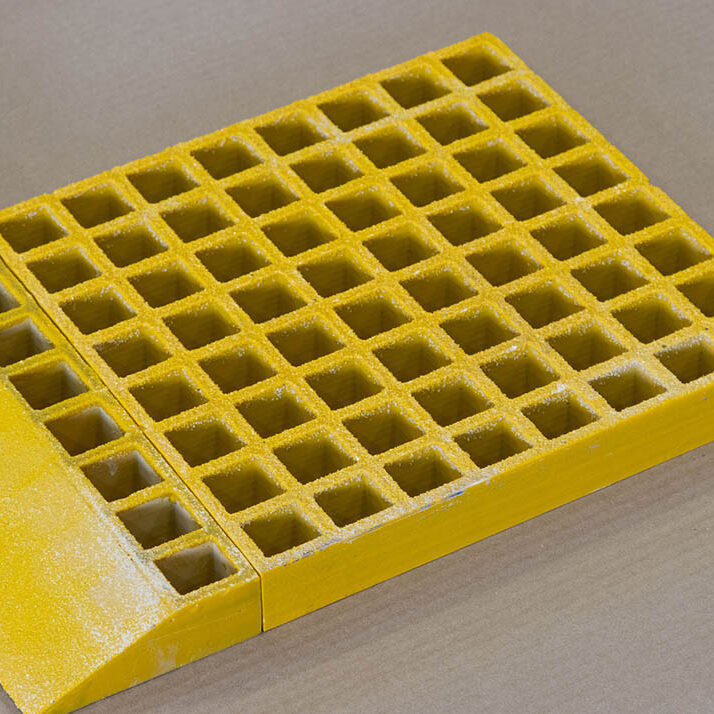

Fibreglass Ladder Rung Covers

Our FRP (Fibre Reinforced Polymer) ladder rung covers, also known as fibreglass ladder rung covers, are strong, lightweight, and corrosion-resistant. It offers excellent grip for safe climbing in commercial and industrial settings, with long-term performance in demanding environments.

Safety and Quality Above the Standard

What Sets us Apart

We are a New Zealand family-owned and operated company with a fully equipped workshop in the Bay of Plenty. We provide an in-house cutting service supported by advanced equipment and proven fabrication methods, and we can accommodate non-standard sizes and finishes when required. Our team is always ready with technical support and practical design guidance, and we maintain significant stock on-site to keep lead times short and projects moving.

-

Production Oversight

Our products are produced exclusively through accredited manufacturing partners that operate under ISO 9001 quality systems. This gives us direct control over specifications, consistency, and traceability.

-

Verified Testing and Compliance

Our products are independently tested and verified to recognised standards, supported by third-party laboratories and CPEng engineering where required, ensuring dependable performance.

-

Environmental Responsibility

We are guided by ISO 14001:2015 environmental management principles to reduce waste, improve efficiencies, and minimise our operational impact.

Length: 3000 mm

External width: 50 mm

External depth: 14 mm

Thickness: 3 mm

Isophthalic polyester (ISO) – general purpose grade resin suitable for minimal contact with harsh chemicals

We offer various anti-slip grit finishes designed to match your environment:

Fine Grit (125-210 µm | Approximately P120–P80 to FEPA Classification): Barefoot-friendly and comfortable underfoot, perfect for public walkways, aquatic areas, schools, and anywhere people may be in lighter footwear or barefoot.

Medium Grit (600 µm | Approximately P40 to FEPA Classification): The trusted choice for general, commercial, and industrial use, providing reliable slip resistance in workshops, plants, and high-traffic areas.

With both options, you get the right balance of safety, comfort, and performance.

Testing was carried out by SGS. in accordance with ASTM D570-22 on our moulded FRP products manufactured using ISO and VE resin systems.

Test Conditions:

Dried at 50 ± 2 °C for 24 h

Soaked in water at:

- 23 °C for 24 h

- 100 °C for 2 h

- 50 °C for 48 h

Measured Water Absorption (%):

|

Condition |

Sample A |

Sample B |

Assessment |

|

23 °C / 24 h |

0.17 % |

0.09 % |

Excellent resistance – negligible absorption |

|

100 °C / 2 h |

0.49 % |

0.47 % |

High stability – minimal uptake under heat |

|

50 °C / 48 h |

0.52 % |

0.71 % |

Strong retention – remains below 1 % threshold |

Interpretation:

Results demonstrate consistently low water absorption across all temperature and duration tests, confirming a dense, well-cured laminate structure.

Moisture uptake remained below 1 %, supporting dimensional accuracy, mechanical reliability, and long-term surface integrity.

Performance levels are within the expected range for high-grade structural FRP composites and trend toward the lower end of typical absorption values, indicating slightly improved resistance compared with standard industry benchmarks.

Our colour system utilises a polyester-based pigment dispersion that chemically bonds within the FRP matrix, rather than just coating it. This 100 % solids, low-VOC formulation delivers cleaner processing, longer-lasting colour, and superior UV stability compared to solvent-borne alternatives. It’s a smarter, more sustainable way to colour FRP.

Testing was carried out by SGS in accordance with ASTM D495-22 and ASTM D149-20 on our FRP moulded products manufactured using ISO and VE resin systems.

Test Conditions:

- Dry Arc Resistance (ASTM D495-22)

• Arcing voltage: 12.5 kV • Electrode gap: 6.35 mm • Environment: 23 °C / 50 % RH - Dielectric Breakdown (ASTM D149-20)

• Transformer oil medium • Voltage rise: 3000 V/s • Frequency: 50 Hz

Measured Electrical Performance:

|

Property |

Sample A (ISO resin) |

Sample B (VE resin) |

Assessment |

|

Arc Resistance Time (s) |

182.5 s |

146.2 s |

Excellent surface insulation – high resistance to tracking |

|

Dielectric Strength (kV/mm) |

15.6 kV/mm |

12.5 kV/mm |

Strong electrical barrier – stable under high voltage |

Interpretation:

Results confirm both resin systems deliver high-grade electrical insulation consistent with the requirements of ASTM D495 and D149.

The ISO-resin laminate achieved the highest overall performance, showing extended arc-resistance duration and greater dielectric strength, indicating a dense, well-cross-linked matrix with minimal conductive pathways.

The VE-resin laminate also exhibited strong insulating capability, remaining well within the range expected for premium structural FRP composites.

Electrical performance across both systems supports their suitability for installations requiring high-voltage isolation, reduced surface tracking, and long-term reliability in wet or industrial environments.

Available Colours

The colour range shown is an artist impression only, actual colours may vary.

Why Choose FRP Ltd

-

NZ Family-Owned and Operated

We understand what matters to you as a proudly NZ family-owned and operated business. We're dedicated to providing reliable, locally supported solutions that meet the needs of New Zealand industries.

-

Expertise and Quality

We offer our customers premium products that adhere to industry standards, ensuring durability and reliability.

-

Competitive Pricing

We deliver exceptional value by combining high-quality materials with cost-effective pricing, ensuring you receive the best products at a reasonable cost.

-

Proven Track Record

We are proud to have built a reputation nationwide and across industries for delivering reliable product solutions that meet and exceed customer expectations.

Have a Question? Get Product Advice.

We're here to help! If you have any questions, need support with a product, or would like a copy of the standards we adhere to, please don't hesitate to contact us. We look forward to assisting you!