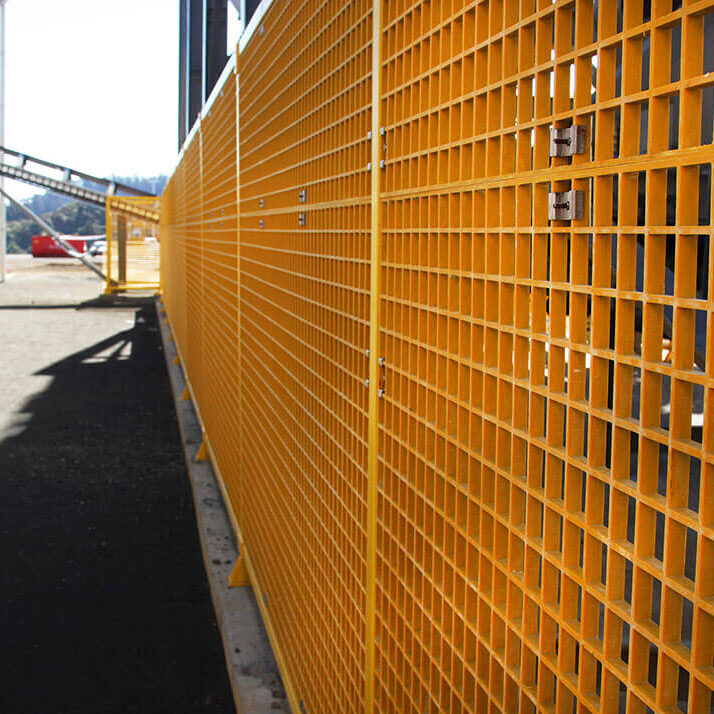

For fencing, barriers, and machine guarding.

Case Study:

FRP Solutions for Meat Rendering

Challenge

The client required a durable, low-maintenance solution for their met rendering plant, which operates in a highly corrosive environment. They needed platforms, stairs, walkways, and guarding systems to withstand harsh conditions, ensure safety, and support heavy loads, including fully loaded forklifts.

Solution

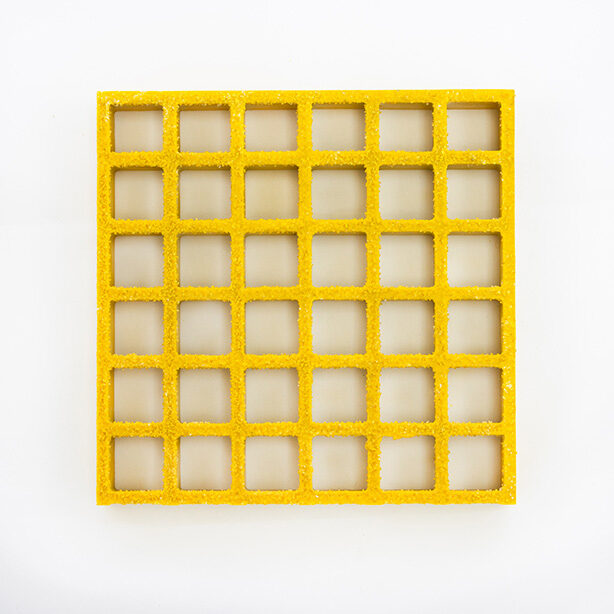

They selected our FRP products for their non-corrosive nature, high slip resistance, and durability in industrial and hazardous environments. Our FRP grating was easy to cut with standard power tools, allowing for hassle-free installation across various applications such as platforms, stairs, walkways, drain strips, and working zones at both height and ground level.

Our modular guarding system provided an effective alternative to steel, which is prone to deterioration in corrosive environments. This system enhanced workplace safety by protecting personnel from potential hazards near operating machinery. The guarding system included an interlock feature that shuts off machinery when the gate opens and panels that are easy to remove during maintenance operations.

Outcome

Installing our FRP systems improved safety and efficiency at the meat rendering plant. The customisable, cut-to-size options ensured that the FRP products met the specific needs of each application, enhancing overall operational efficiency and safety for the plant’s workforce.