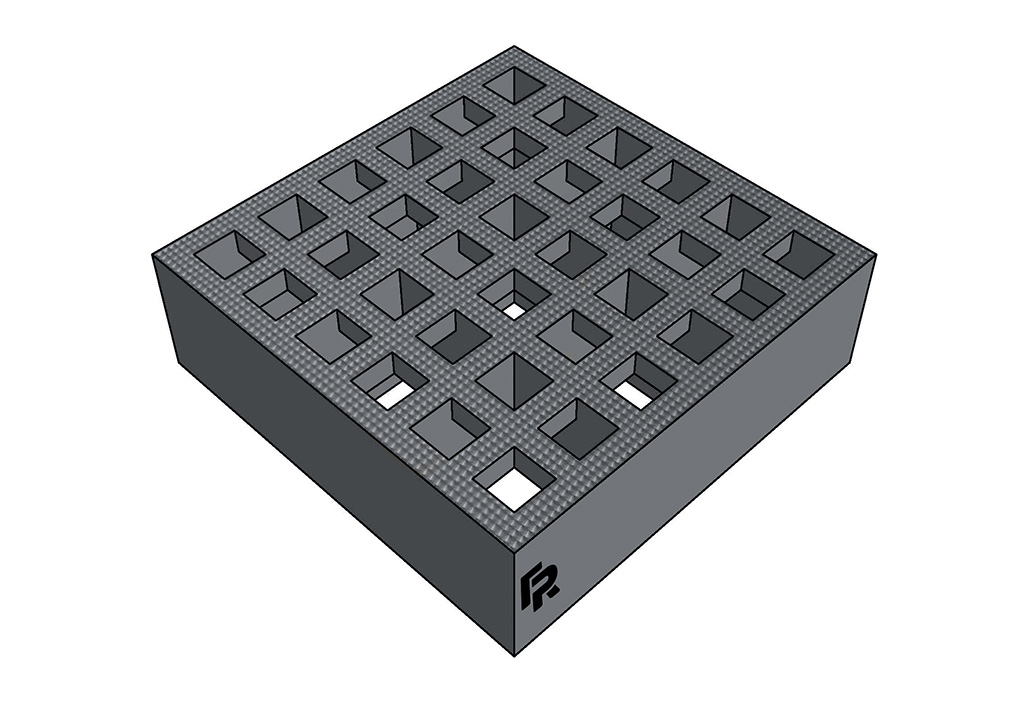

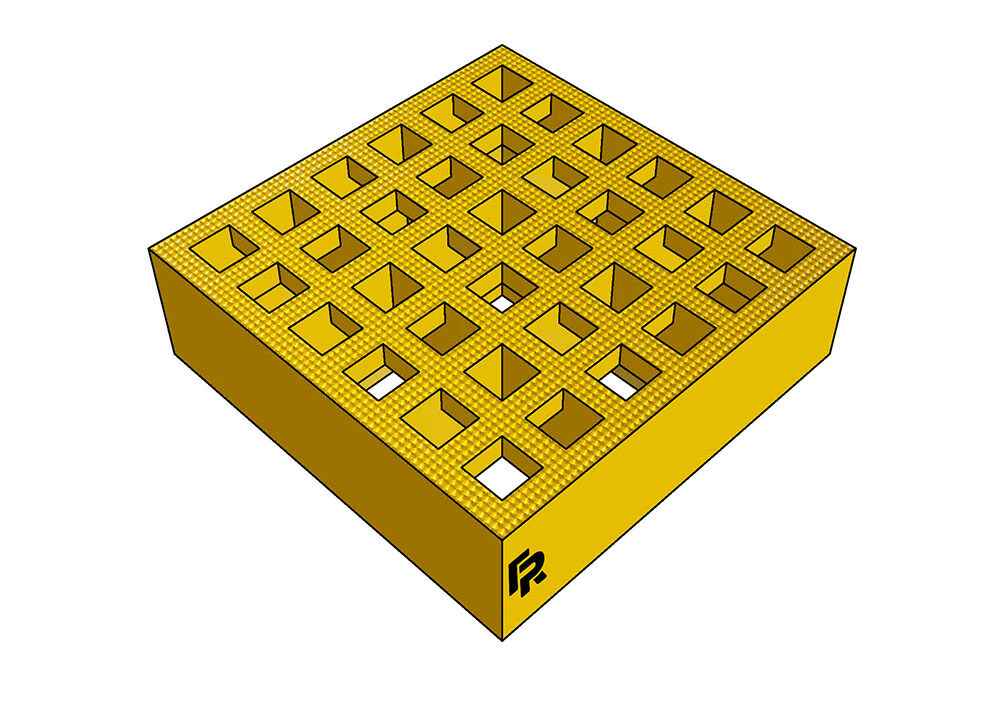

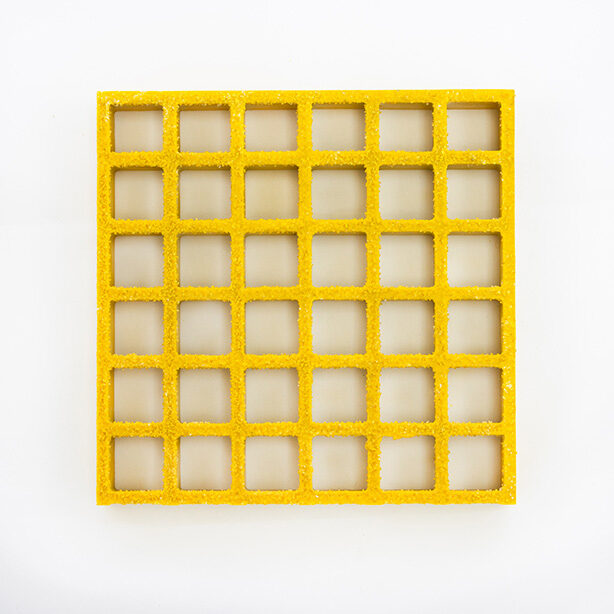

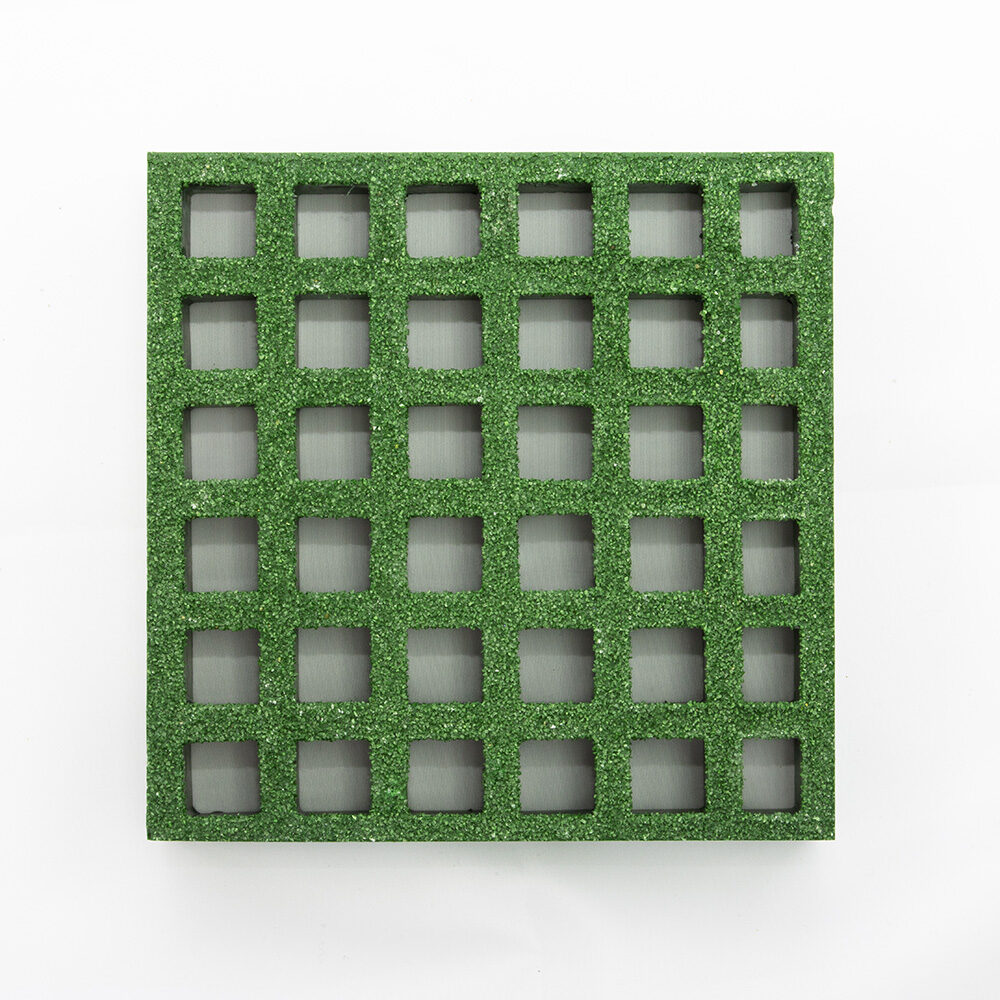

Our most commonly used mesh product. 38 x 38 mm (31 x 31 mm) aperture. Medium (general grade) grit surface.

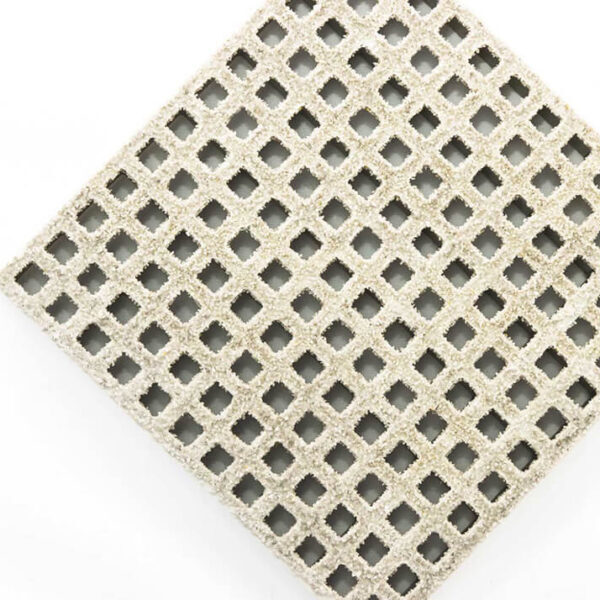

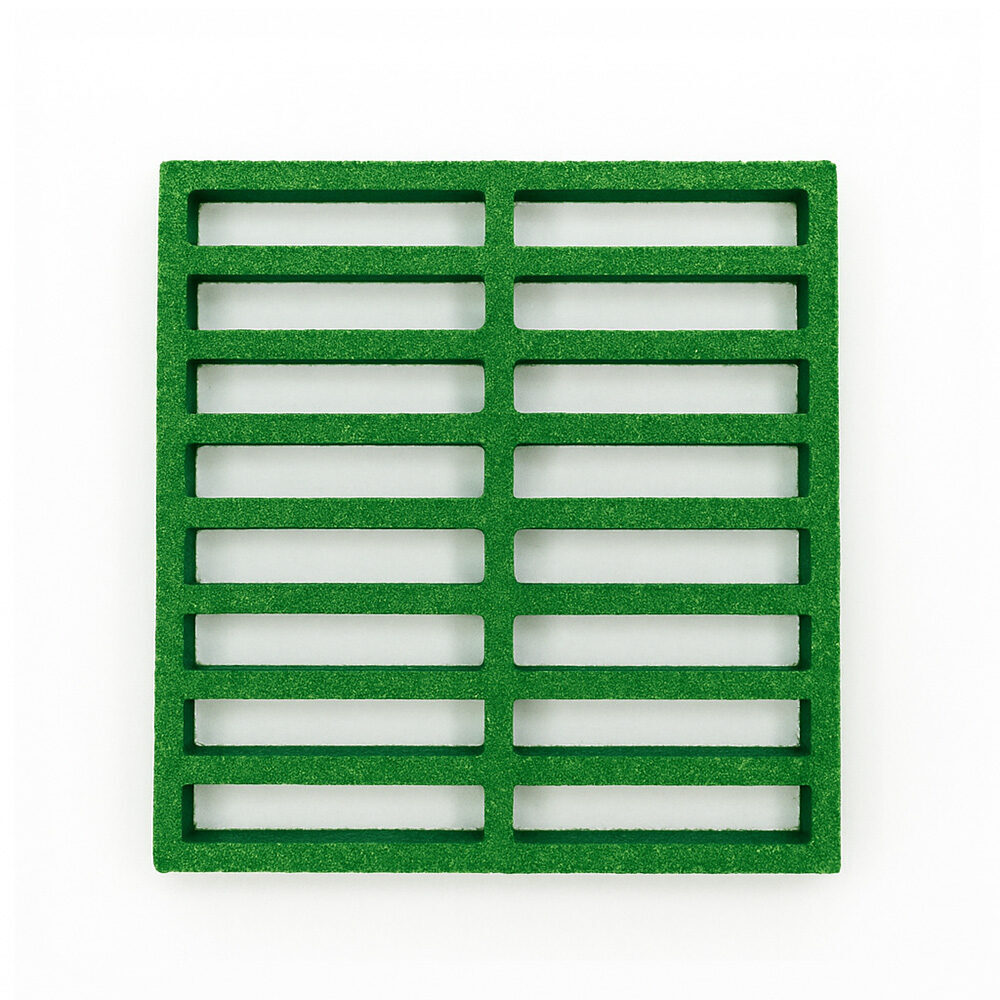

Fibreglass Mini Mesh Grating

FRP (Fibre Reinforced Polymer), also commonly known as fibreglass, mini mesh grating features a 12 mm aperture, preventing objects from falling through from overhead platforms and walkways. This versatile grating product is ideal for industrial, marine, commercial, residential, and public space applications. It is highly resistant to slips and corrosion, durable, low-maintenance, and easy to install.

Safety and Quality Above the Standard

What Sets us Apart

We are a New Zealand family-owned and operated company with a fully equipped workshop in the Bay of Plenty. We provide an in-house cutting service supported by advanced equipment and proven fabrication methods, and we can accommodate non-standard sizes and finishes when required. Our team is always ready with technical support and practical design guidance, and we maintain significant stock on-site to keep lead times short and projects moving.

-

Production Oversight

Our products are produced exclusively through accredited manufacturing partners that operate under ISO 9001 quality systems. This gives us direct control over specifications, consistency, and traceability.

-

Verified Testing and Compliance

Our products are independently tested and verified to recognised standards, supported by third-party laboratories and CPEng engineering where required, ensuring dependable performance.

-

Environmental Responsibility

We are guided by ISO 14001:2015 environmental management principles to reduce waste, improve efficiencies, and minimise our operational impact.

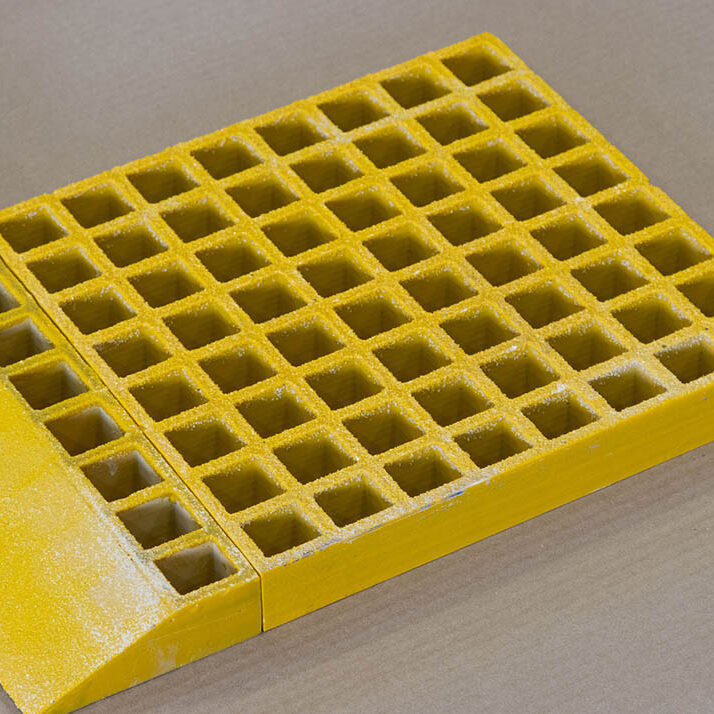

Our moulded FRP grating is manufactured using the hand lay-up and open mould casting process, combining strength, durability, and customisability in every panel.

How it Works:

Fibreglass reinforcements (roving or mat) are manually layered in both directions into a heated open mould (hand lay-up). Resin is then poured or brushed over the fibres (open mould casting) until fully saturated. The panel is cured in-mould, creating a solid, seamless structure with no joints or weak points.

Why This Process Matters:

Bidirectional Strength: Reinforcements are placed in both directions, giving equal load-bearing capacity across the panel.

Seamless, One-Piece Construction: No joints or welds – excellent durability and delamination resistance.

Customisable Resin System: Vinyl ester, polyester, or phenolic options are available, along with additives such as fire retardants, UV stabilisers, colour pigments, and anti-slip grit.

Ideal for Complex Mesh Designs: Allows for flexible mesh sizes, such as mini mesh and micro mesh.

Excellent Corrosion Resistance: Resin-rich surfaces provide high chemical and UV resistance.

Consistent Quality: The moulded surface ensures uniform bar spacing, thickness, and an anti-slip texture.

Efficient Production: Requires minimal finishing – only edge trimming and optional coating.

Load bar spacing: 38 x 38 mm (12 x 12 mm aperture)

25 and 38 mm depth

Dimensions: 3665 (L) x 1226 (W)

Isophthalic polyester (ISO) – general purpose grade resin suitable for minimal contact with harsh chemicals

Vinyl Ester (VE) – superior grade resin formulated to withstand frequent contact with harsh chemicals

We offer various anti-slip grit finishes designed to match your environment:

Fine Grit (125-210 µm | Approximately P120–P80 to FEPA Classification): Barefoot-friendly and comfortable underfoot, perfect for public walkways, aquatic areas, schools, and anywhere people may be in lighter footwear or barefoot.

Medium Grit (600 µm | Approximately P40 to FEPA Classification): The trusted choice for general, commercial, and industrial use, providing reliable slip resistance in workshops, plants, and high-traffic areas.

With both options, you get the right balance of safety, comfort, and performance.

FIRE PERFORMANCE

- ISO 9239-1 / AS 9239.1 (Reaction to Fire for Flooring Materials) – Tested by NZWTA Laboratories (Reports 2018 & 2020).

Critical Radiant Flux (CRF): 10.9 kW/m² – Exceeds the 4.5 kW/m² requirement for NZ & Australia.

Smoke Value: ≈ 210 %.min – Very low smoke generation, excellent visibility retention.

Result: Fully compliant with NZ Building Code (C/VM2) and Australian NCC equivalence - ASTM E84 – Steiner Tunnel Test – SGS Report (Dec 2022).

Flame Spread Index (FSI): 20 • Smoke Developed Index (SDI): 400 Classification: Class A (≤ 25 FSI / ≤ 450 SDI) — highest U.S. rating.

DURABILITY & UV EXPOSURE

- ASTM G154 Accelerated UV Exposure – Samples exposed 2,500 hours (≈ 7–10 years real-world) showed no statistically significant strength loss

- Complies with NZ Building Code Clause B2 (Durability).

- Expected service life well beyond 15 years with routine maintenance.

MATERIAL SAFETY

- AS 4964 (Qualitative Identification of Asbestos) – Independent testing confirmed no asbestos detected in any FRP Limited product.

WATER ABSORPTION TESTING

Testing was carried out by SGS. in accordance with ASTM D570-22 on our moulded FRP products manufactured using ISO and VE resin systems.

TEST CONDITIONS:

Dried at 50 ± 2 °C for 24 h

Soaked in water at:

- 23 °C for 24 h

- 100 °C for 2 h

- 50 °C for 48 h

MEASURED WATER ABSORPTION (%):

| Condition | Sample A | Sample B | Assessment |

|---|---|---|---|

| 23°C / 24 h | 0.17% | 0.09% | Excellent resistance – negligible absorption |

| 100 °C / 2 h | 0.49% | 0.47% | High stability – minimal uptake under heat |

| 50 °C / 48 h | 0.52% | 0.71% | Strong retention – remains below 1% threshold |

INTERPRETATION:

Results demonstrate consistently low water absorption across all temperature and duration tests, confirming a dense, well-cured laminate structure.

Moisture uptake remained below 1%, supporting dimensional accuracy, mechanical reliability, and long-term surface integrity.

Performance levels are within the expected range for high-grade structural FRP composites and trend toward the lower end of typical absorption values, indicating slightly improved resistance compared with standard industry benchmarks.

LOW VOC PIGMENT

Our colour system utilises a polyester-based pigment dispersion that chemically bonds within the FRP matrix, rather than just coating it. This 100% solids, low-VOC formulation delivers cleaner processing, longer-lasting colour, and superior UV stability compared to solvent-borne alternatives. It’s a smarter, more sustainable way to colour FRP.

ELECTRICAL PROPERTIES – TESTING IN PROGRESS

- Arc Resistance (LW): ASTM D-495 – pending

- Dielectric Strength (LW): ASTM D-149 – pending

- Dielectric Strength (PW): ASTM D-149 – pending

SLIP RESISTANCE

- AS/NZS 4586 (Wet Pendulum Method) – Independently tested by ISTS (NATA Accredited).

- All surfaces classified V – Very Low Risk of Slip (BPN > 54).

- Complies with NZBC Clauses D1 (Access Routes) and F4 (Safety from Slipping).

ELECTRICAL INSULATION TESTING

Testing was carried out by SGS in accordance with ASTM D495-22 and ASTM D149-20 on our FRP moulded products manufactured using ISO and VE resin systems.

TEST CONDITIONS:

Dry Arc Resistance (ASTM D495-22)

- Arcing voltage: 12.5 kV • Electrode gap: 6.35 mm • Environment: 23 °C / 50 % RH

Dielectric Breakdown (ASTM D149-20)

- Transformer oil medium • Voltage rise: 3000 V/s • Frequency: 50 Hz

MEASURED ELECTRICAL PERFORMANCE:

| Property | Sample A (ISO resin) | Sample B (VE resin) | Assessment |

|---|---|---|---|

| Arc Resistance Time (s) | 182.5 s | 146.2 s | Excellent surface insulation – high resistance to tracking |

| Dielectric Strength (kV/mm) | 15.6 kV/mm | 12.5 kV/mm | Strong electrical barrier – stable under high voltage |

INTERPRETATION:

Results confirm both resin systems deliver high-grade electrical insulation consistent with the requirements of ASTM D495 and D149.

The ISO-resin laminate achieved the highest overall performance, showing extended arc-resistance duration and greater dielectric strength, indicating a dense, well-cross-linked matrix with minimal conductive pathways.

The VE-resin laminate also exhibited strong insulating capability, remaining well within the range expected for premium structural FRP composites.

Electrical performance across both systems supports their suitability for installations requiring high-voltage isolation, reduced surface tracking, and long-term reliability in wet or industrial environments.

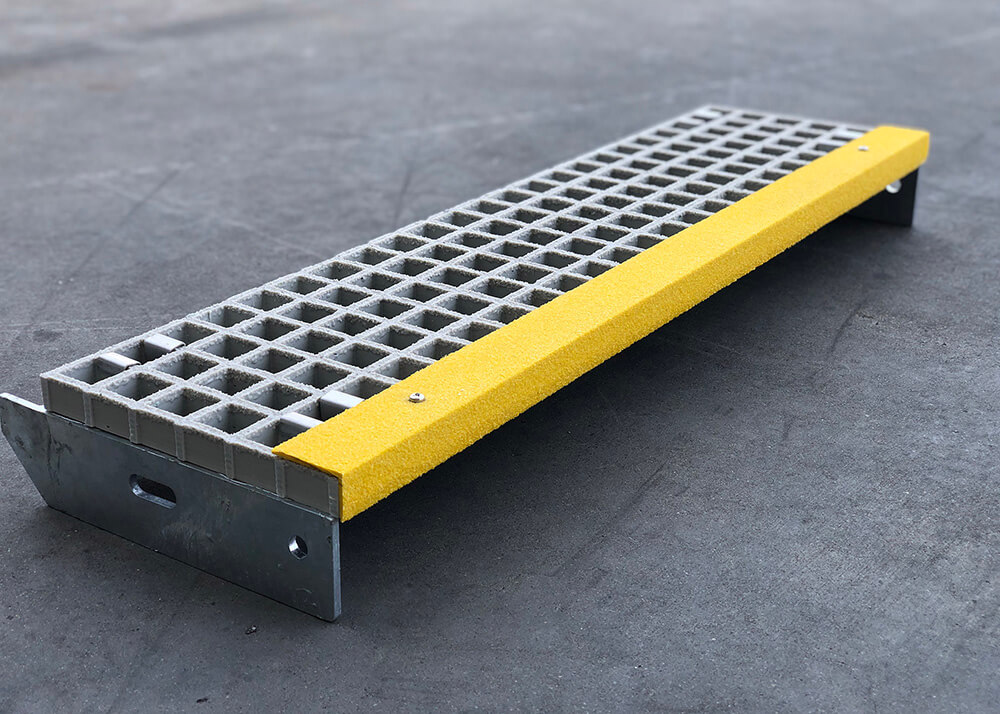

Fabrication & Cutting Services

We operate a full in-house fabrication facility supplying grating pre-cut, sealed and installation ready.

Capabilities Include:

- CNC panel saws for precision straight-line and batch cutting

- Waterjet cutting for curved, shaped, or penetrated layouts

- Edge banding available from the factory on an indent basis

- In-house resin sealing of all cut edges for moisture and UV protection

- Custom fabrication of framed assemblies and colour-contrasted sections

Full FRP panels are produced to a typical dimensional tolerance of +/- 2 mm. When custom cutting is required, the final supplied size is confirmed during the design process. Desired finished dimensions must allow for saw kerf and the location of load bars, since some cuts may pass directly through a load bar which can influence the achievable tolerance. Our team works through these considerations at quotation stage so that supplied panels land as close as possible to the intended finished size.

Fabrication is performed in New Zealand using FRP-approved resins and traceable production batches. Panels can be supplied to fit drawings, pre-drilled or framed for fast installation.

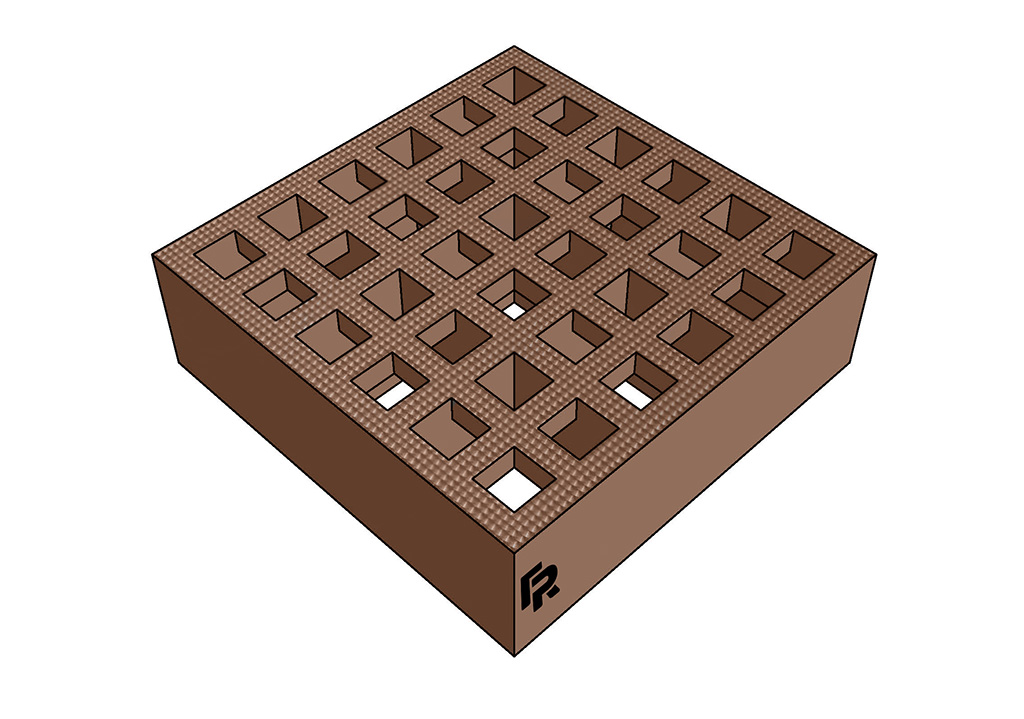

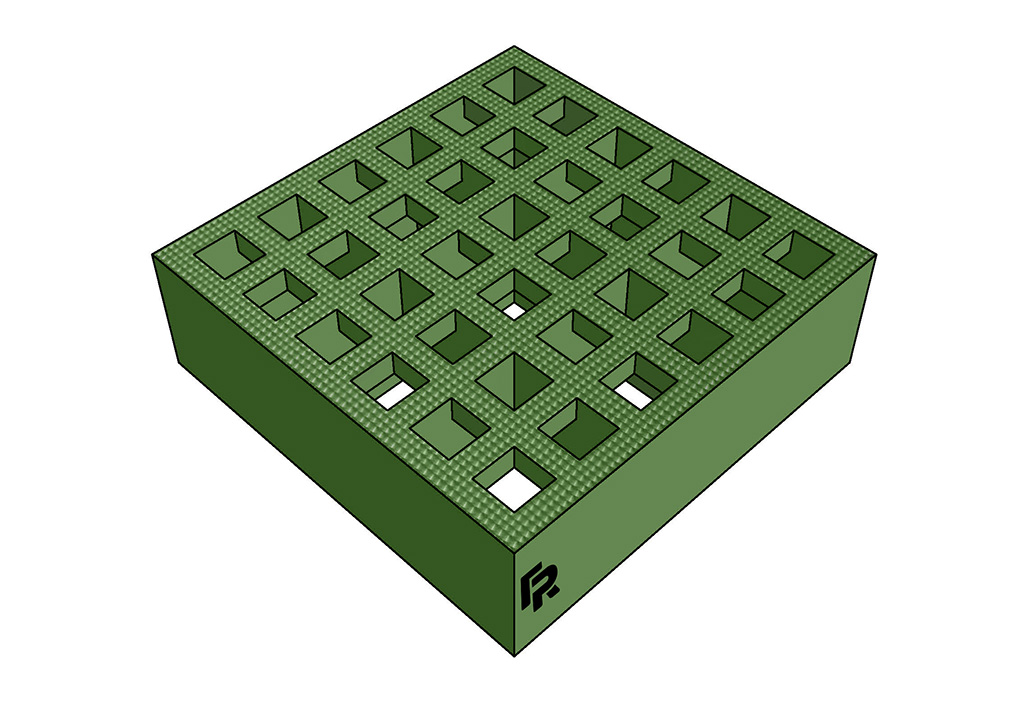

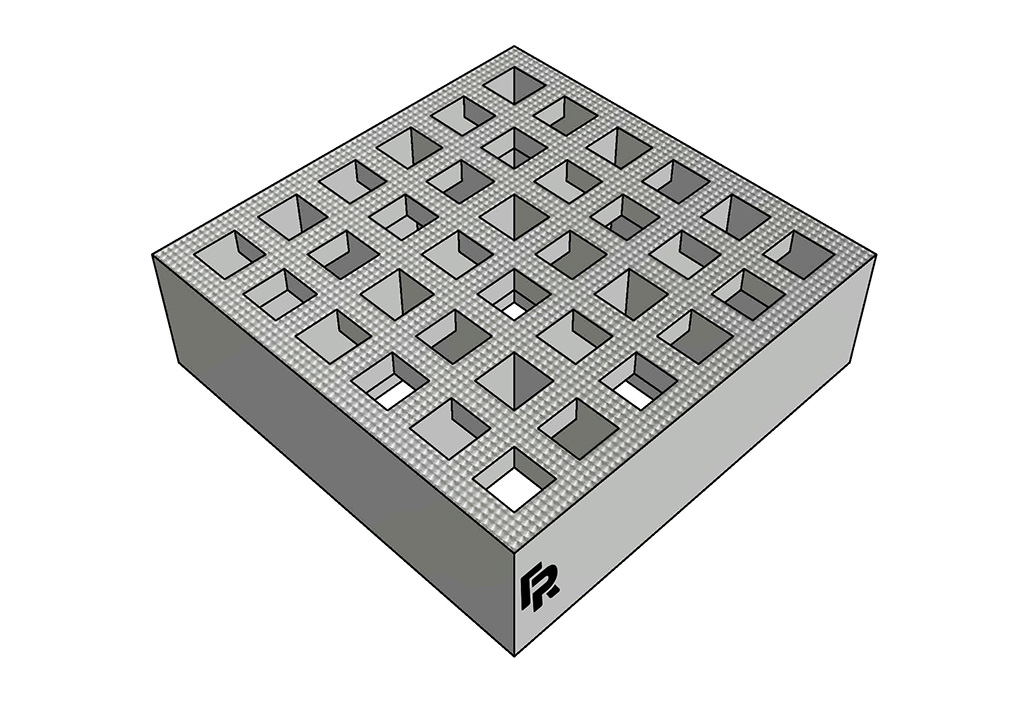

Available Colours

The colour range shown is an artist impression only, actual colours may vary.

PDF Downloads

Case Studies

Why Choose FRP Ltd

-

NZ Family-Owned and Operated

We understand what matters to you as a proudly NZ family-owned and operated business. We're dedicated to providing reliable, locally supported solutions that meet the needs of New Zealand industries.

-

Expertise and Quality

We offer our customers premium products that adhere to industry standards, ensuring durability and reliability.

-

Competitive Pricing

We deliver exceptional value by combining high-quality materials with cost-effective pricing, ensuring you receive the best products at a reasonable cost.

-

Proven Track Record

We are proud to have built a reputation nationwide and across industries for delivering reliable product solutions that meet and exceed customer expectations.

Have a Question? Get Product Advice.

We're here to help! If you have any questions, need support with a product, or would like a copy of the standards we adhere to, please don't hesitate to contact us. We look forward to assisting you!

Ancillary Products

Related Products

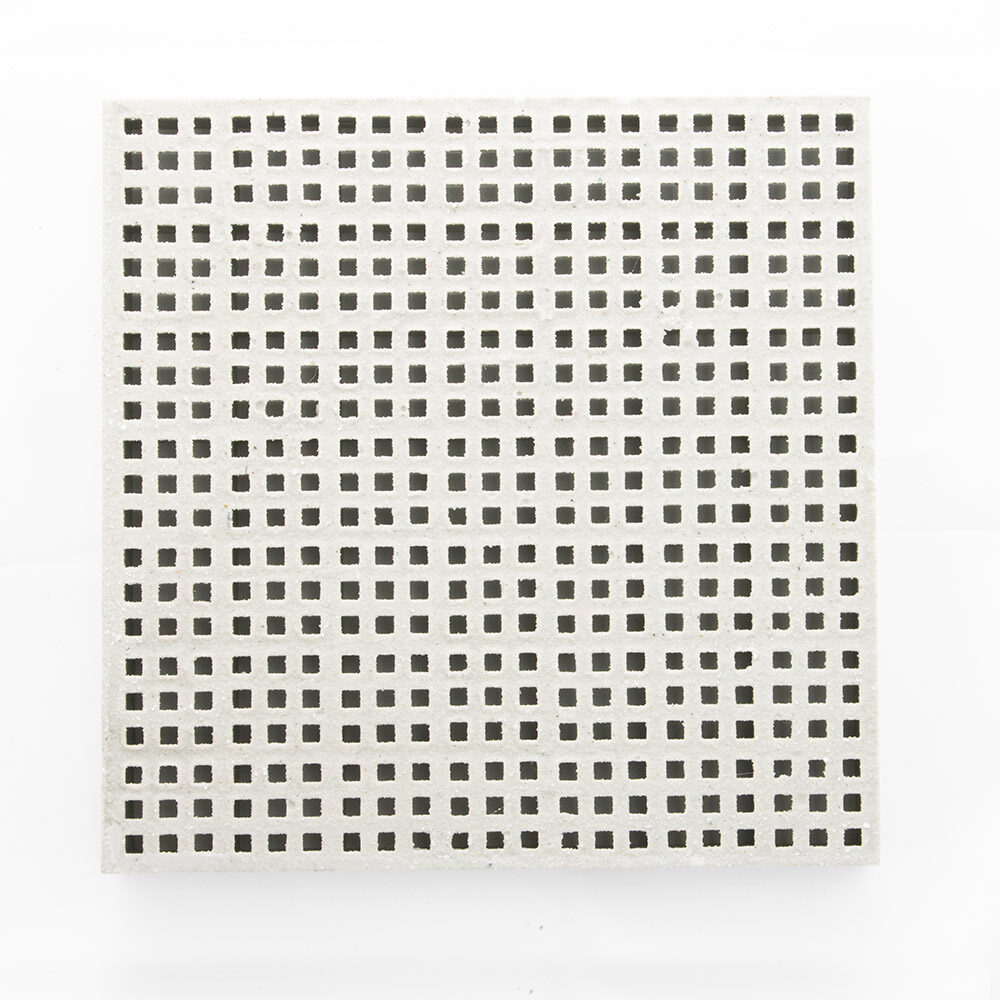

Fibreglass Micro Mesh Grating

Has the smallest aperture for foot-friendly applications. 38 x 38 mm (7 x 7 mm aperture). Fine (barefoot friendly) grit surface.

Fibreglass Cover Top Grating

For when an enclosed top surface is required. 38 x 38 mm. Medium (general grade) grit surface.

Fibreglass Heavy Duty Mesh Grating

For extra-heavy duty applications. 38 x 38 mm (26 x 26 mm aperture). Medium (general grade) grit surface.

Fibreglass Access Mesh Grating

For rooftop walkway access systems. 38 x 38 mm (31 x 31 mm aperture). Medium (general grade) grit surface.